Features

Quiet, Compact & Energy Efficient.

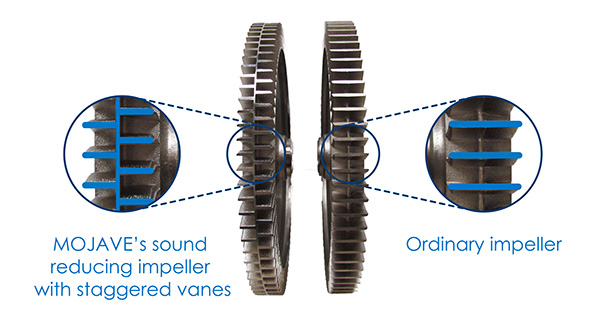

- Sound-reducing impeller design

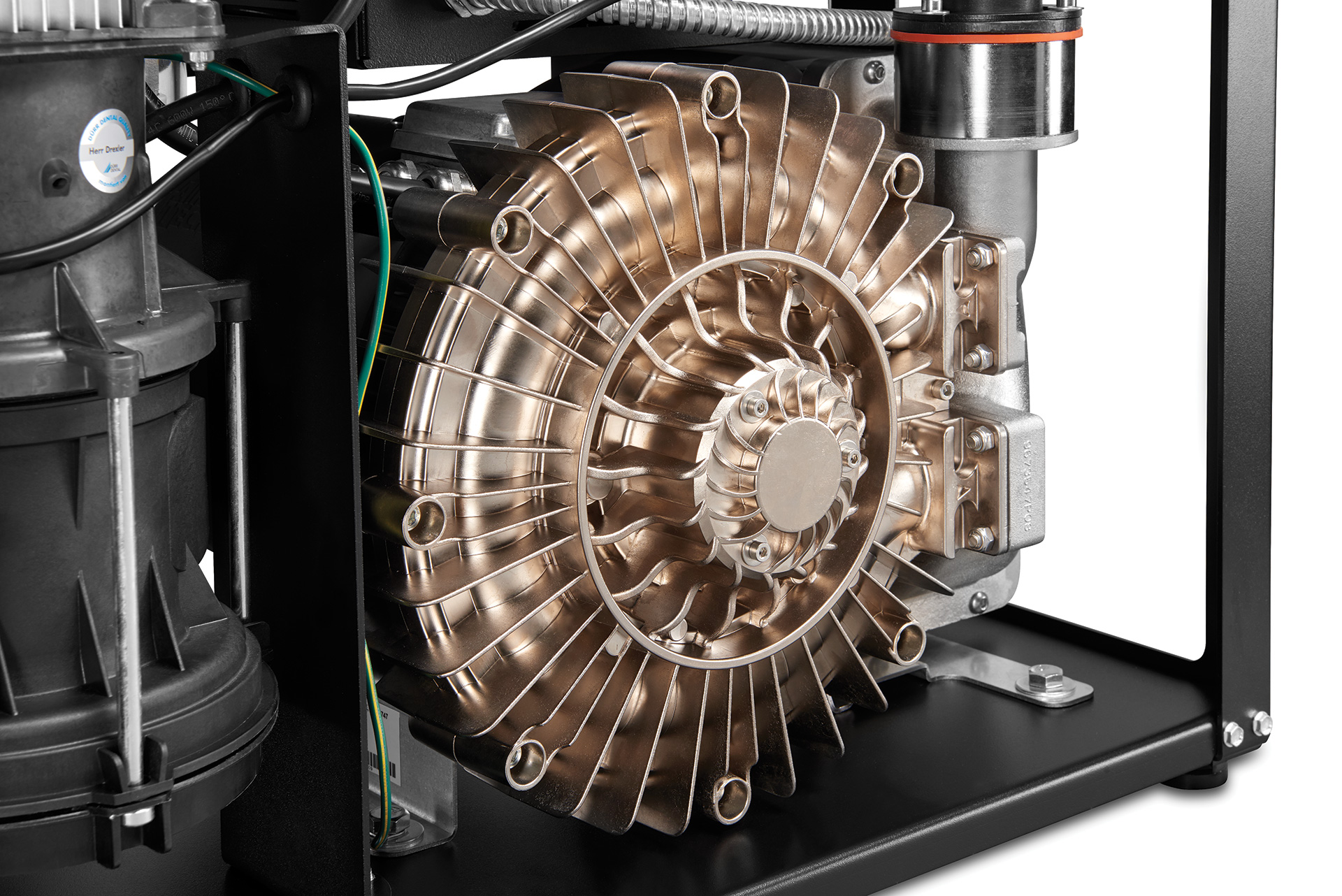

- 3-phase motor generates higher torque and less heat

- Extended heat-resistant motor bearings

- All wetted metal parts are nickel plated or stainless steel

- Aluminum high performance air-exhaust heat exchanger

- Rugged metal chassis

Mojave Control System

The Mojave LT Series automatically adjusts the speed of the pump to maintain vacuum level regardless of how many users come online. A vacuum transducer senses when a HVE or SE is opened, increasing the frequency of the 3-phase motor to quickly provide the flow rate needed on-demand.

- Energy-efficient system that prolongs the life of your pumps

- Monitors and displays pump frequency, vacuum level, temperature & separator RPMs

- Set vacuum level from 8 to 10 inHg

- Records the run time in hours

- Displays any error/fault codes

- Controls the diagnosis functions

- Connects to NEO Pulse front-of-office software

VISION MONITOR

Real-Time Monitoring

Vision Monitor brings valuable information from your critical dental equipment directly to those who need to see it. Through cloud-based IoT monitoring, get live status updates, device messages, and the ability to provide remote support and configuration. Whether you are managing equipment from a single office or 200 or more offices, Vision Monitor has features to ensure your equipment will quickly, and easily notify you with detailed, relevant information.

Intelligence, Simplified

• SPECIFIC: Don’t get lost in charts and information overload. Vision monitor provides clear, pertinent information for you to keep your equipment running.

• SCALABLE: Whether you are monitoring a single office, or 200 or more, Vision Monitor can support your needs.

• SECURE: Encryption and data security up to the highest industry standards

• SENSIBLE: No additional hardware required! Use the existing assets in your office to connect your devices to the cloud.*

*No additional hardware is required to connect to Vision Monitor on equipment with an existing network connection. Connect Box is required to monitor legacy equipment.

Contact

Contact