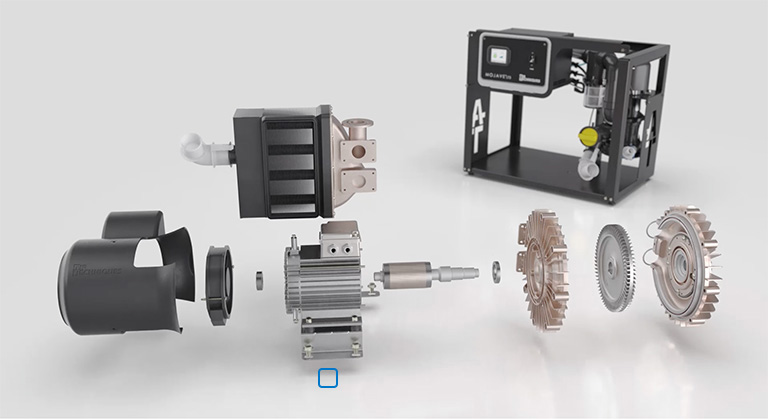

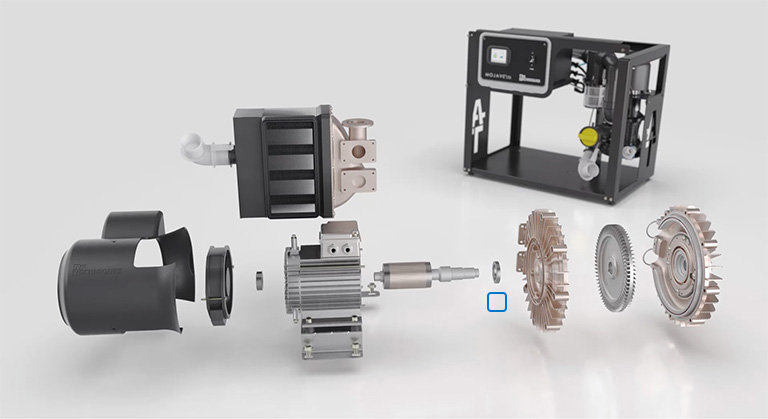

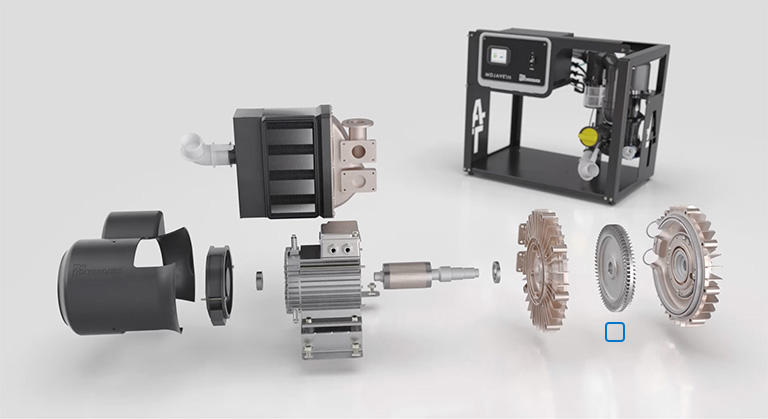

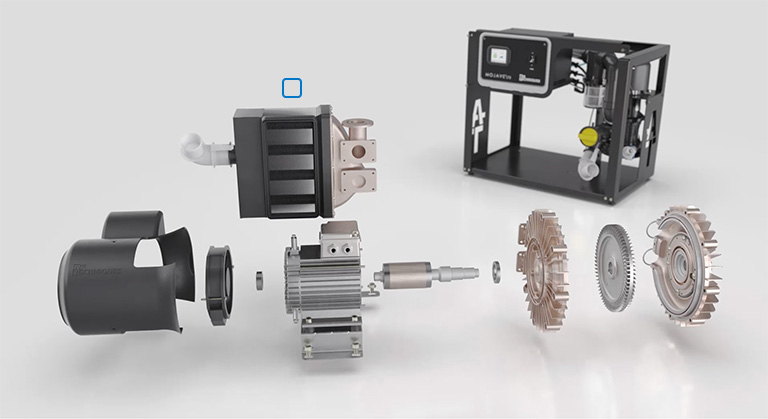

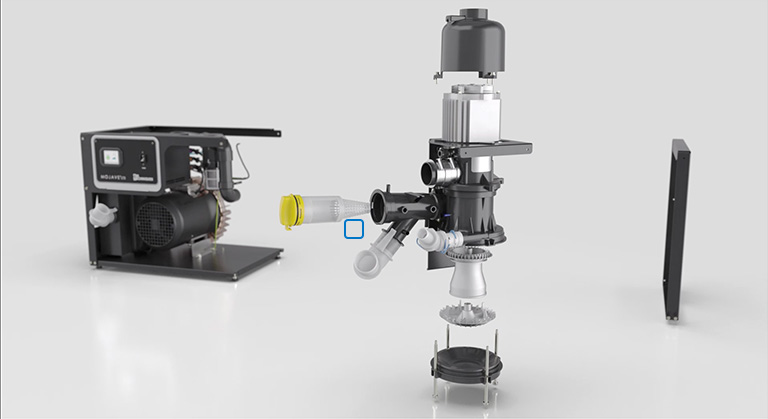

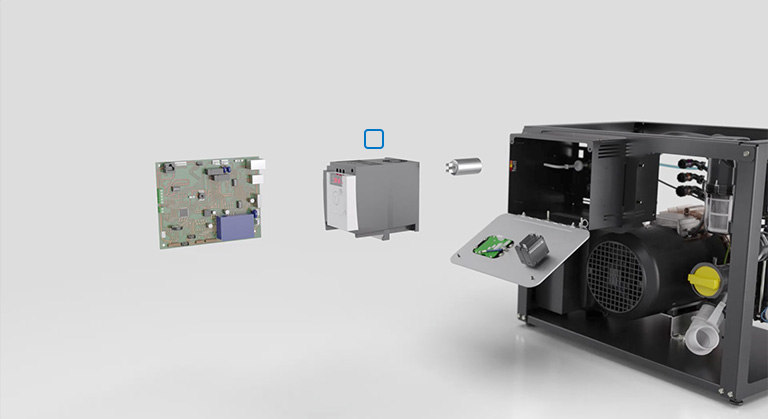

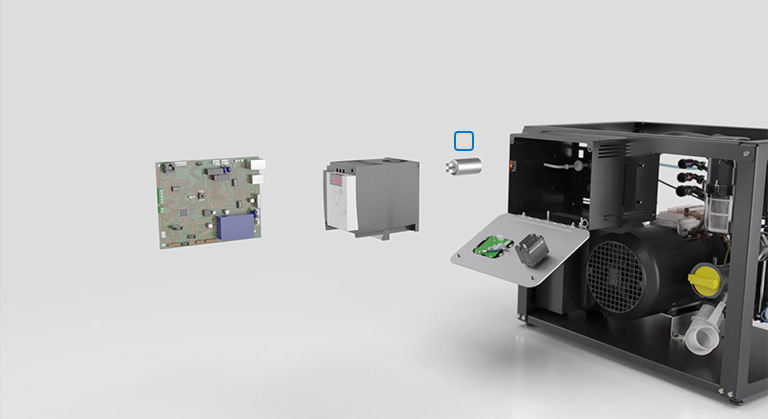

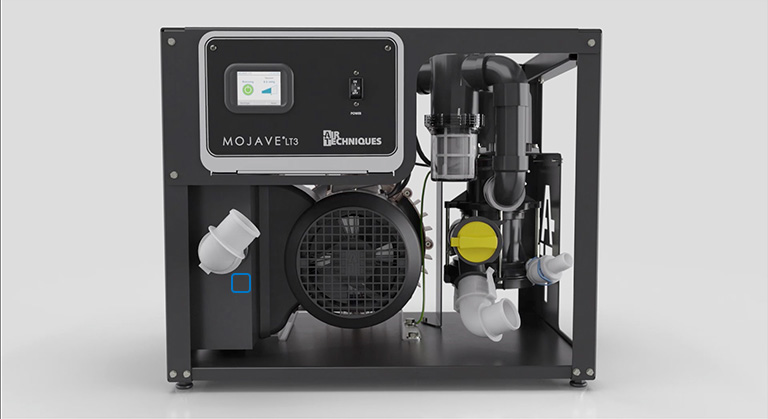

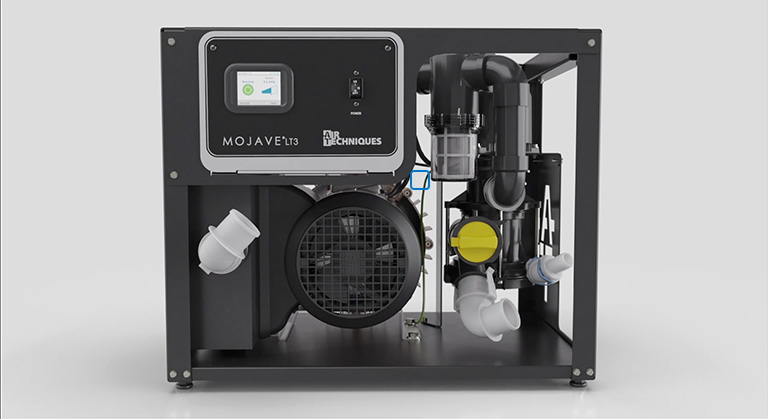

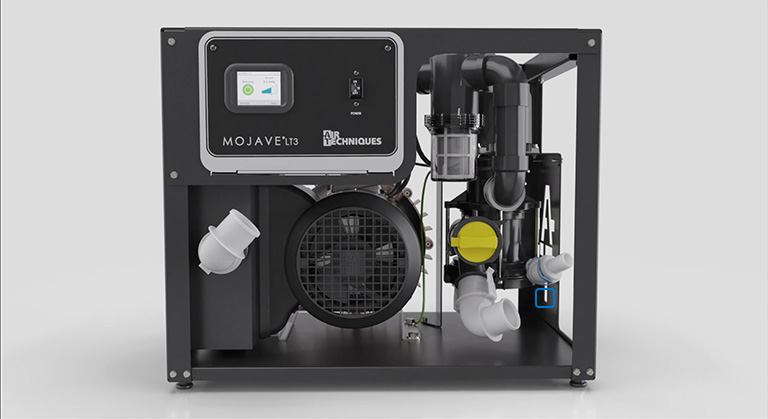

Motor Breakout Explode

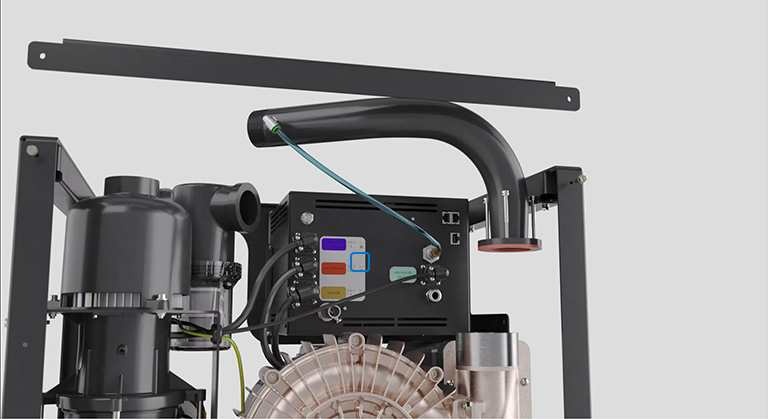

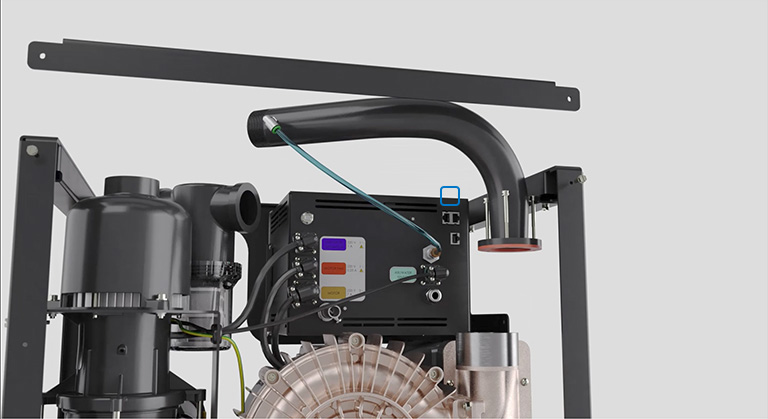

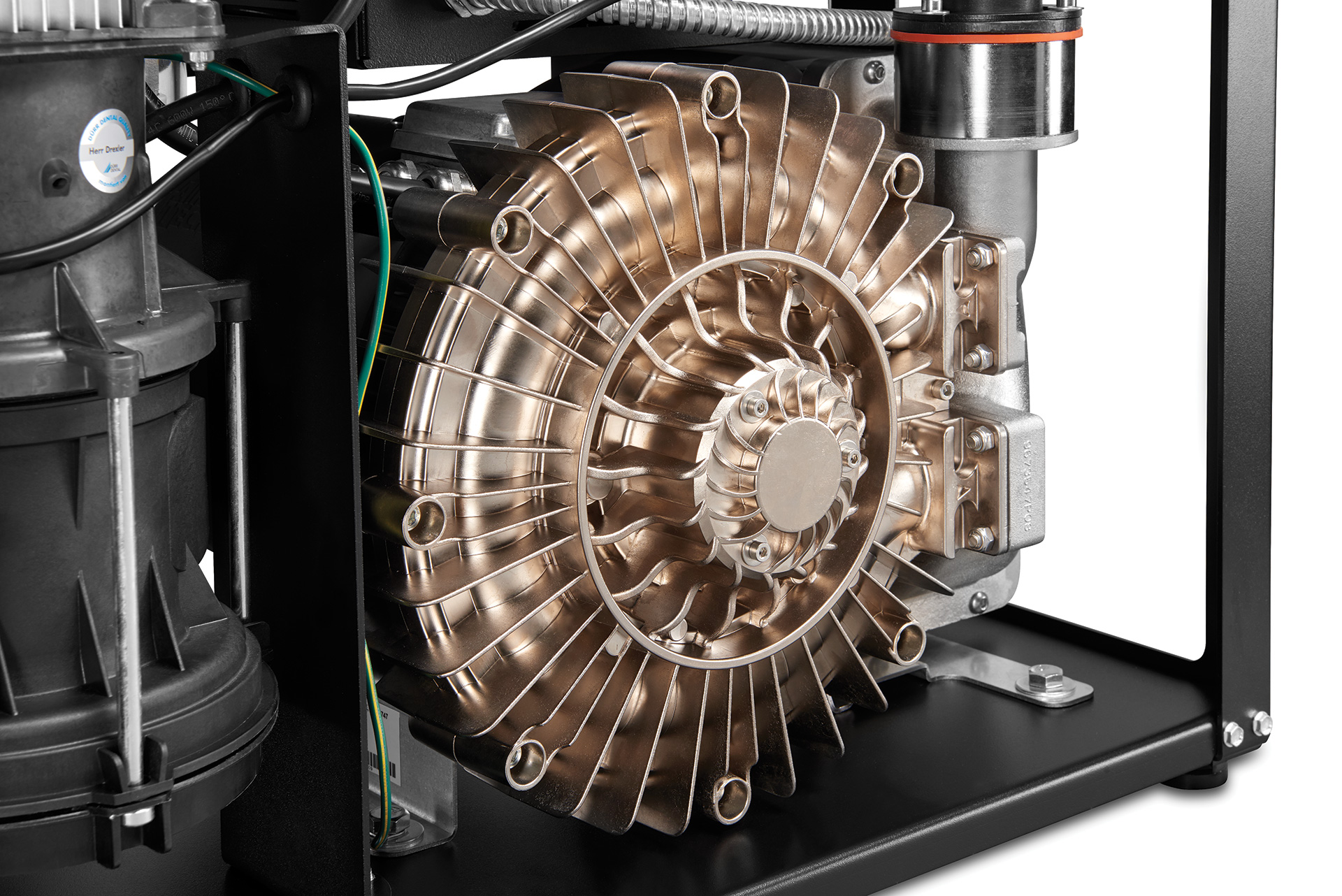

- Single Stage Blower

- Variable Speed

- Continuous Duty

- Thermal Sensor

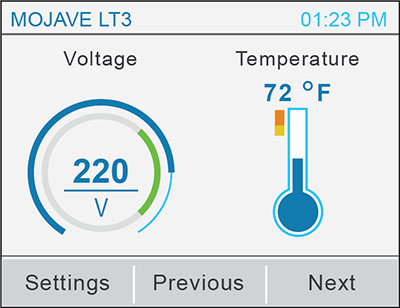

- 220V 50/60 Hz

- 1.5 HP

- 10,000 RPM

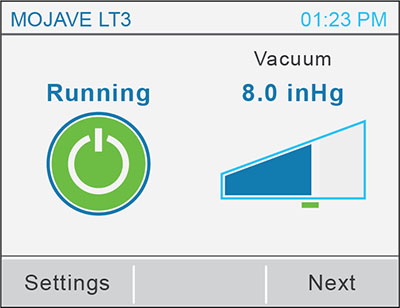

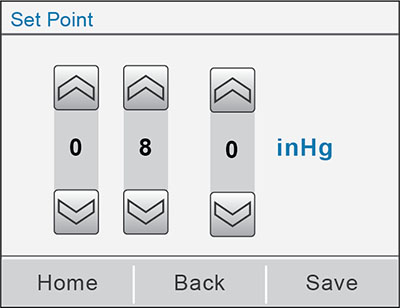

- 8 – 10 inHg

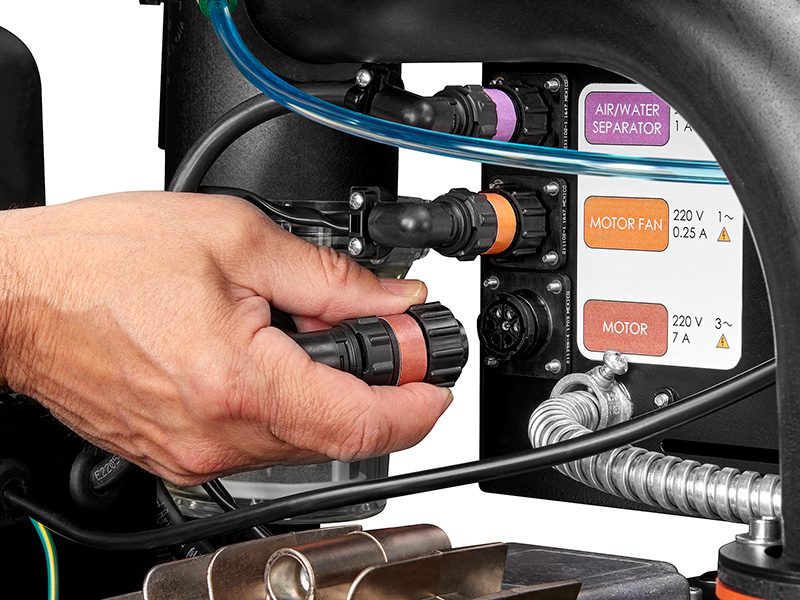

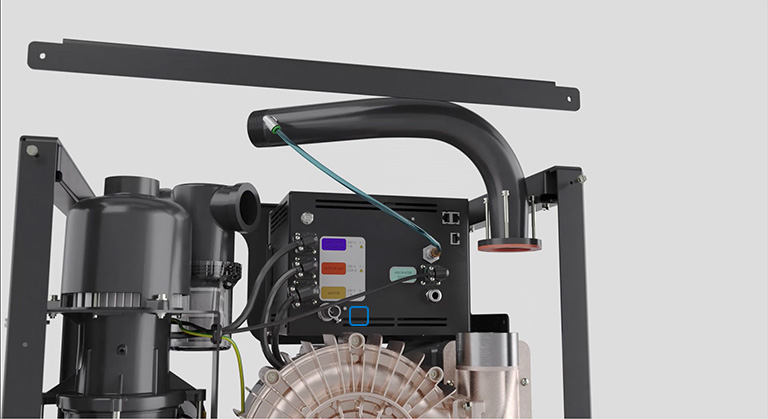

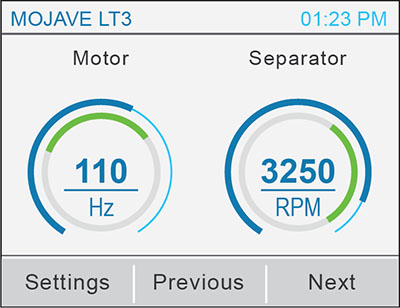

The three-phase variable speed motor speeds up and slows down based on demand. This saves energy by not running the motor at full speed when HVEs are closed. With a fast response rate, the motor automatically delivers the needed flow rate in real time while being completely transparent to the user.

The industrial double sealed radial ball bearings are rated up to 350º Made of pressed steel and using molded synthetic rubber to contain high-temperature grease.

The bearings are positioned away from the heat source for optimal performance, reliability and long life.

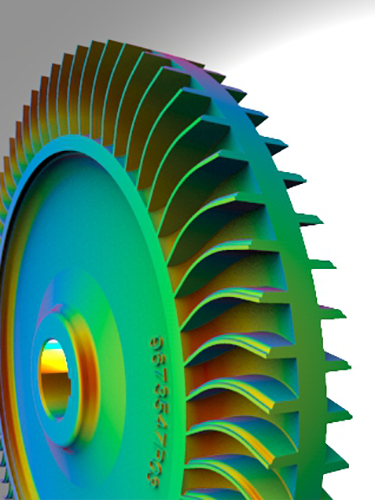

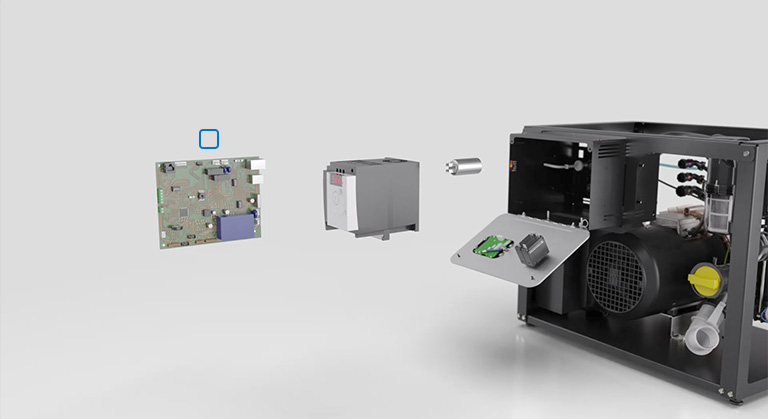

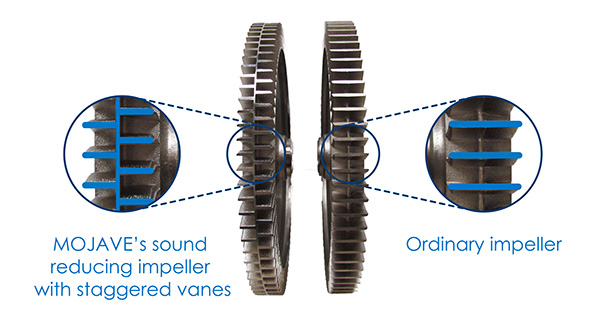

The precision investment casted and machined aluminum impeller utilizes a vane pattern that is engineered to deliver high performance while reducing annoying sound discharge. Using finite element analysis, the vanes have a geometry that is precisely engineered to maximize flow and energy efficiency.

All internal components are made of either aluminum or stainless steel and all aluminum surfaces are nickel plated by electrolysis. All wetted surfaces are assembled using stainless steel fasteners.

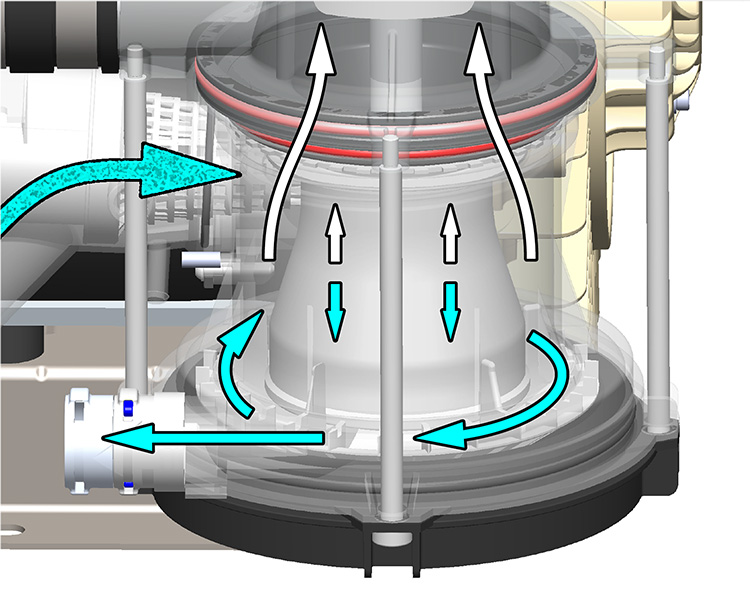

Heat generated from the pump is transferred into the primary air flow where the heat exchanger’s fins cool the air before it is exhausted.

The heat exchanger is engineered to exhaust only 10ºF maximum above ambient room temperature.

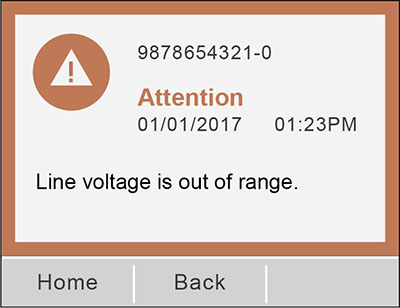

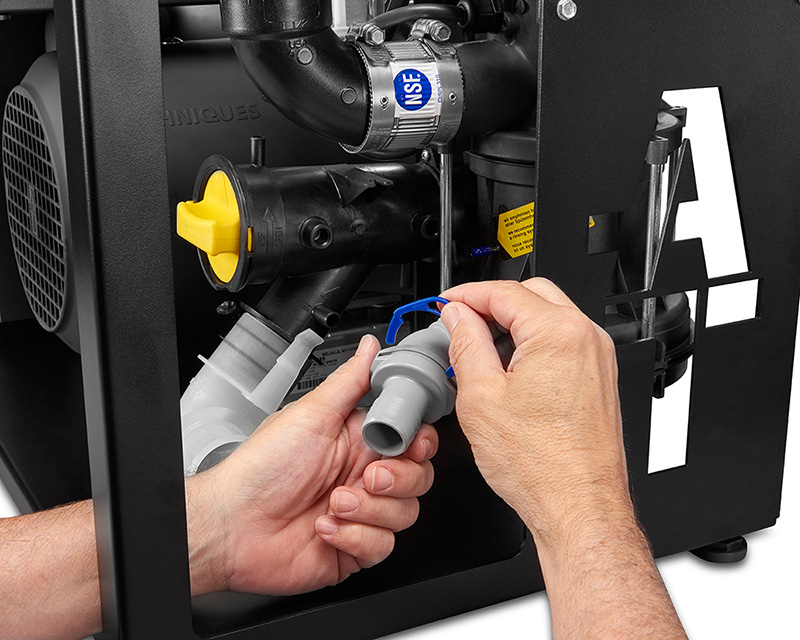

Contact

Contact